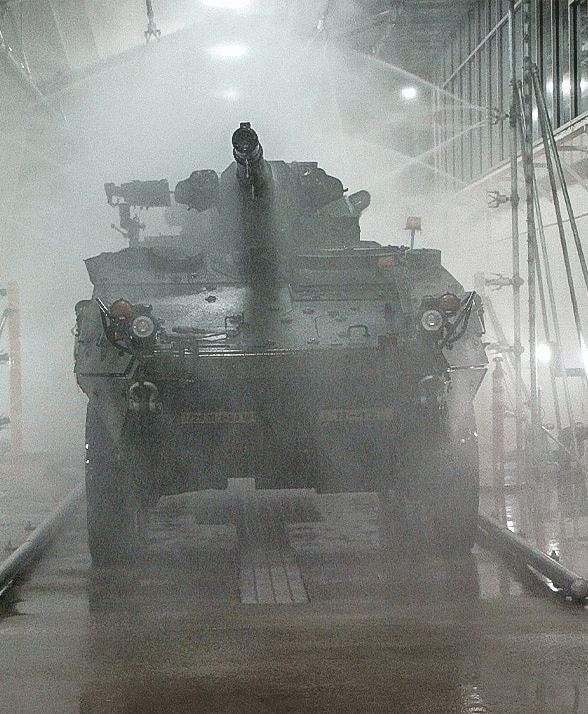

It takes a washing stand equipped with a high pressure hose, four crewmen and a Sergeant First Class who’s a real prick who will stick his pinkie finger into some tiny crevice in the tracks and pullout some mud and yell “It’s not clean! Keep washing!” The prick index goes up by a factor of 10 when the tank crew includes a 2nd Lieutenant. I speak from experience.

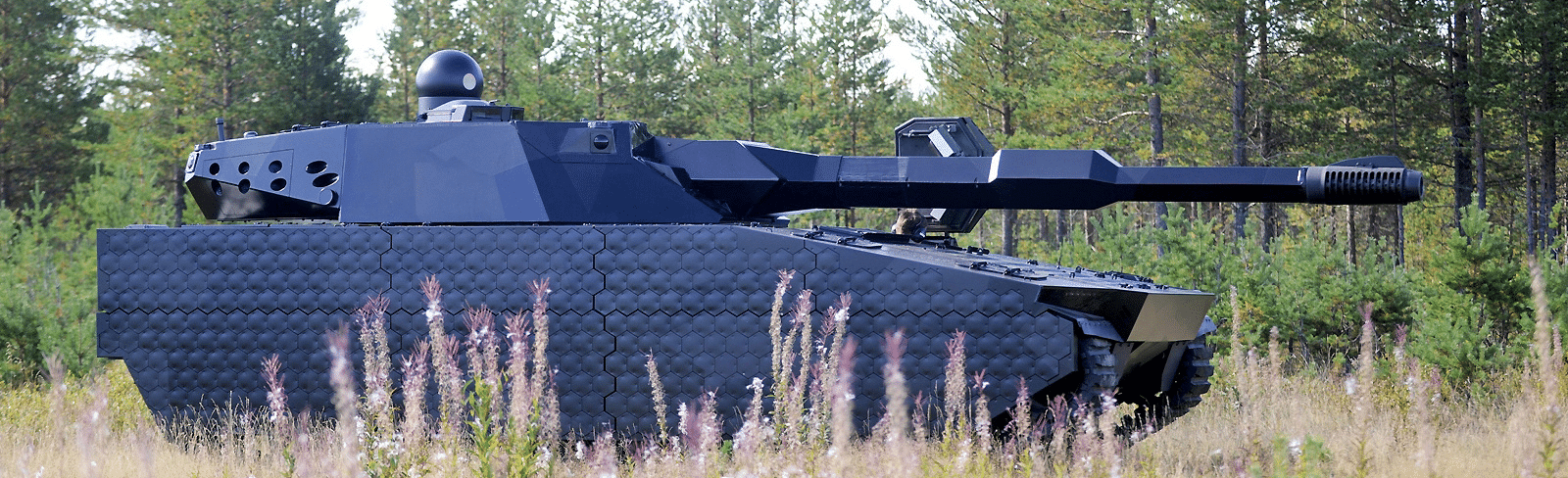

Are you looking to keep your armored multi-purpose vehicles and military tanks in top-notch condition? Look no further! In this comprehensive guide, we delve into the world of automatic wash systems for heavy armored ground vehicles. From the importance of automated cleaning processes to the intricate design considerations and implementation steps, we’ve got you covered. Discover how these cutting-edge systems not only save time but also ensure optimal cleanliness and efficiency for iconic vehicles like BAE CV90, Bradley Fighting Vehicle, and more. Let’s dive in and explore the future of military vehicle maintenance together!

Brief overview of the necessity of armored vehicle cleaning

- Importance of automating the wash process

- Objectives of the automatic wash system for armored vehicles

When it comes to military tanks and heavy armored ground vehicles, regular cleaning is not just about aesthetics—it’s a crucial aspect of maintenance. The harsh environments these vehicles operate in can lead to the buildup of dirt, grime, and other contaminants that can impact performance and longevity. That’s where automating the cleaning process becomes invaluable.

Automating tank washing offers a range of benefits over traditional manual methods. It streamlines the cleaning process, ensuring consistent results while saving time and resources. By implementing an automatic wash system, you can achieve thorough cleanliness without the need for extensive manual labor.

The objectives of an automatic wash system are clear: efficiency, effectiveness, and safety. These systems aim to provide a convenient solution for maintaining military vehicles by optimizing water and detergent usage while minimizing risks to personnel and equipment.

Armored Vehicle Automatic Wash Design Considerations

- A. Compatibility with various tank and armored vehicle models and sizes

- B. Efficiency in water and detergent usage;

- C. Safety measures for both personnel and equipment

- D. Integration with existing maintenance infrastructure

When designing an automatic wash system for military tanks and heavy armored vehicles, compatibility with various tank models and sizes is crucial. The system must be versatile enough to accommodate different shapes and sizes without compromising effectiveness.

Efficiency in water and detergent usage is another key consideration. Minimizing water wastage while ensuring thorough cleaning helps reduce operational costs and environmental impact.

Safety measures for both personnel and equipment are paramount. Implementing safeguards such as emergency stop buttons, motion sensors, and protective covers can prevent accidents during the washing process.

Integration with existing maintenance infrastructure streamlines operations by allowing seamless connectivity between the wash system and other maintenance facilities. This ensures a cohesive workflow that maximizes efficiency across all areas of vehicle care.

Components of the Armored Vehicle Automatic Wash System

- A. High-pressure water jets

- 1. Distribution system

- 2. Pressure regulation mechanism

- B. Detergent dispensing unit

- 1. Storage tanks

- 2. Pumping system

- 3. Mixing mechanism

- C. Scrubbing brushes or pads

- 1. Material selection

- 2. Motion control system D. Rinse cycle

- D. High Pressure Rinse

- 1. Clean water supply

- 2. Rinse nozzles

- E. Drying system

- 1. Air blowers

- 2. Heating elements

When it comes to the components of an automatic wash system for military tanks and heavy armored vehicles, each element plays a crucial role in ensuring thorough cleaning and maintenance.

Starting with high-pressure water jets, the distribution system is designed to cover every nook and cranny of the vehicle, while the pressure regulation mechanism ensures optimal cleaning power without causing damage.

The detergent dispensing unit consists of storage tanks for holding cleaning solutions, a pumping system for efficient delivery, and a mixing mechanism to create the perfect blend for removing tough grime.

Scrubbing brushes or pads are carefully selected for their durability and effectiveness in dislodging dirt, coupled with a motion control system that moves them precisely over the vehicle’s surface.

During the rinse cycle, clean water supply is essential along with rinse nozzles strategically positioned to remove any remaining residue effectively.

To complete the process, the drying system utilizes air blowers and heating elements to ensure a spotless finish on the armored vehicle.

Armored Vehicle Automatic Wash Implementation Steps

- A. Site preparation

- 1. Selection of location

- 2. Installation of necessary infrastructure (water supply, drainage)

- B. Procurement of components

- 1. Sourcing high-pressure water jets, detergent dispensers, etc.

- 2. Quality assurance checks

- C. Assembly and installation

- 1. Mounting components on a sturdy framework

- 2. Electrical and plumbing connections

- D. Testing and calibration

- 1. Functional testing of each component

- 2. Adjustments for optimal performance

- E. Training and documentation

- 1. Training personnel on operating procedures

- 2. Maintenance schedule and documentation

When it comes to implementing an automatic wash system for military tanks and heavy armored vehicles, a series of steps must be followed diligently. The site preparation is crucial – selecting the right location ensuring easy access to water supply and drainage systems is essential for smooth operations.

Next, procurement of components involves sourcing high-quality equipment such as high-pressure water jets and detergent dispensers. Quality assurance checks should be conducted rigorously to guarantee optimal performance.

Assembly and installation require mounting all components securely on a sturdy framework while making necessary electrical and plumbing connections. Testing and calibration follow this step to ensure each part functions correctly with adjustments made as needed for peak efficiency.

Training personnel on operating procedures is vital for seamless operation, coupled with documenting maintenance schedules to keep track of upkeep requirements. This meticulous approach ensures the automatic wash system operates flawlessly at all times.

Operation and Maintenance of Armored Vehicle Automatic Wash Systems

- A. Routine operation procedures

- 1. Initiating the wash cycle

- 2. Monitoring the process

- B. Preventive maintenance

- 1. Regular inspections

- 2. Lubrication and cleaning of components

- C. Troubleshooting and repairs

- 1. Identifying common issues

- 2. Procedures for component replacement

When it comes to operating and maintaining an automatic wash system for military tanks and heavy armored vehicles, routine procedures are key. Initiating the wash cycle should be a straightforward process, ensuring that all components are activated correctly.

Monitoring the process is essential to guaranteeing a thorough clean without any issues. Regular inspections play a crucial role in preventive maintenance, helping to identify potential problems before they escalate.

Lubrication and cleaning of components should be carried out regularly to ensure optimal performance and longevity of the automatic wash system. In case of any issues arising, troubleshooting and repairs must be done promptly with established procedures for component replacement as needed.

Benefits of an Armored Vehicle Automatic Wash System

- A. Time-saving compared to manual cleaning methods

- B. Consistency in cleaning quality

- C. Reduction in water and detergent usage

- D. Improved safety for personnel

When it comes to cleaning military tanks and heavy armored vehicles, time is of the essence. An automatic wash system saves valuable time compared to manual cleaning methods. By automating the process, you can efficiently clean multiple vehicles in a fraction of the time it would take manually.

Consistency is key when it comes to maintaining the quality of cleaning for these specialized vehicles. An automatic wash system ensures that each vehicle receives the same level of thorough cleaning every time. This consistency helps prolong the lifespan of the equipment by preventing dirt buildup and corrosion.

In addition to saving time and ensuring consistent results, an automatic wash system also reduces water and detergent usage. The system is designed to optimize resource utilization while still delivering impeccable cleaning performance.

Moreover, implementing an automatic wash system improves safety for personnel involved in vehicle maintenance. By minimizing direct contact with harsh chemicals or high-pressure water jets, the risk of injuries or accidents is significantly reduced.

Benefits of heavy-duty undercarriage wash system for military tanks and armored vehicles

When it comes to military tanks and armored vehicles, maintaining the undercarriage is crucial for optimal performance. A heavy-duty undercarriage wash system ensures that dirt, mud, and debris are effectively removed, preventing corrosion and damage to vital components. This not only extends the lifespan of the vehicle but also enhances its operational efficiency on the battlefield.

By investing in a specialized undercarriage wash system, military operators can save time and resources that would otherwise be spent on manual cleaning methods. The automated process ensures thorough cleaning while minimizing water and detergent usage. Additionally, regular undercarriage maintenance reduces the risk of mechanical failures during critical missions.

A heavy-duty undercarriage wash system is a cost-effective solution for keeping military tanks and armored vehicles in peak condition. Its benefits go beyond aesthetics – they directly impact the readiness and reliability of these essential assets on the battlefield.

Importance of de-mudding armored vehicles

De-mudding armored vehicles is a crucial task that cannot be overlooked in military operations. When these heavy vehicles traverse through muddy terrains, they accumulate dirt, grime, and debris on their exteriors. This buildup not only affects the vehicle’s appearance but also poses operational risks.

Removing mud and dirt from armored vehicles is essential to maintain optimal performance levels. The weight of mud can impact fuel efficiency and maneuverability, affecting the vehicle’s overall functionality. Moreover, dried mud can corrode the vehicle’s exterior over time if left unattended.

By de-mudding armored vehicles regularly, military personnel ensure that these vital assets remain in top condition for extended periods. It helps prevent mechanical issues caused by clogged systems or excessive weight due to accumulated debris. De-mudding contributes to the longevity and effectiveness of armored vehicles during critical missions.

Clean armored vehicles get extended life by cleaning.

Maintaining clean armored vehicles is crucial for extending their lifespan and ensuring optimal performance on the battlefield. Regular cleaning not only enhances the appearance of the vehicles but also prevents corrosion and wear caused by dirt, grime, and other contaminants.

By removing mud, dust, and debris from the exterior as well as cleaning vital components like undercarriages, engines, and weapon systems, you can prevent unnecessary damage that may lead to costly repairs or replacements in the long run.

Moreover, proper cleaning helps in identifying any potential issues early on before they escalate into major problems. It allows maintenance teams to inspect for leaks, cracks, or malfunctions that could compromise vehicle functionality during critical missions.

Summary of the armored vehicle automatic wash system’s capabilities

- Potential for future enhancements or upgrades

- Importance of regular maintenance for longevity and efficiency

In wrapping up, the automatic wash system for military tanks and heavy armored ground vehicles offers a comprehensive solution for maintaining cleanliness and operational efficiency. Its high-pressure water jets, detergent dispensing unit, scrubbing brushes, rinse cycle, and drying system work together seamlessly to provide a thorough cleaning process.

Looking ahead, there is potential for future enhancements or upgrades to further improve the system’s performance. Innovations in technology could lead to even more efficient water and detergent usage, faster operation times, and enhanced safety features.

Regular maintenance is crucial in ensuring the longevity and efficiency of the automatic wash system. By following recommended maintenance schedules and procedures diligently, operators can maximize the lifespan of their equipment and continue to benefit from its time-saving capabilities.