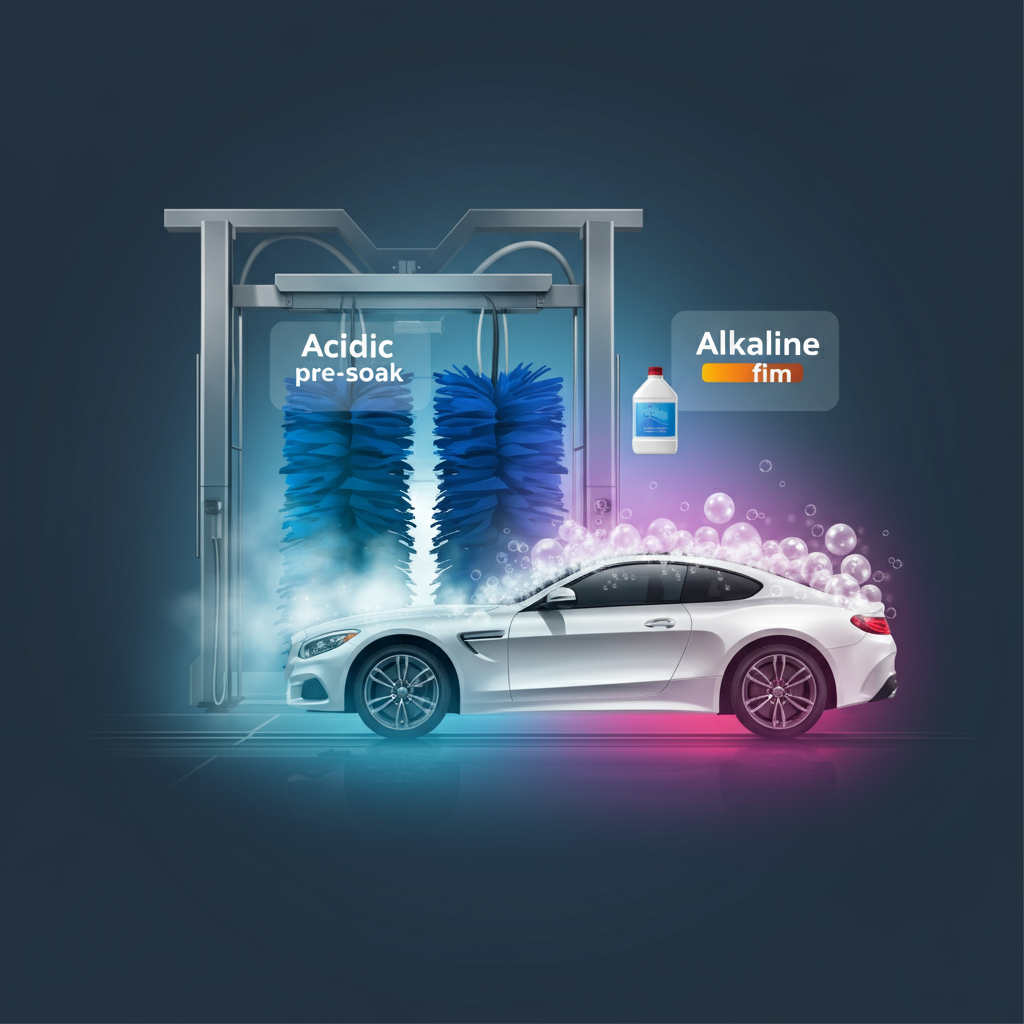

When it comes to keeping vehicles spotlessly clean, effective washing methods are critical—especially for challenges like stubborn road film. One highly effective solution gaining traction in the industry is the two-step washing process. This method, particularly suited for touchless wash systems, combines acidic pre-soaks with alkaline detergents to deliver superior results. Below, we’ll explore the science behind this process, its advantages, and practical implementation tips, along with considerations to keep in mind.

Understanding the Two-step Washing Process

The two-step washing process integrates two key components—an acidic pre-soak followed by an alkaline detergent. Each plays a unique role in breaking down and removing contaminants, making this method particularly adept at tackling the resilient road film common on vehicles.

- Step 1 – Acidic Pre-soak

The process begins with an acidic solution sprayed onto the vehicle surface. This pre-soak is designed to remove inorganic contaminants, like mineral deposits, brake dust, and metallic particles. Acidic solutions excel at breaking bonds between such contaminants and vehicle surfaces, setting the stage for the next step.

- Step 2 – Alkaline Detergent

Once the acid loosens the inorganic materials, an alkaline detergent is applied. Alkaline cleaners are effective at cutting through organic grime, such as grease, oils, and environmental residues. This second step emulsifies and lifts away any remaining dirt, leaving the vehicle clean and ready for rinsing.

The sequential nature of this method ensures a thorough cleaning by targeting different types of contaminants with solutions specifically suited for them.

The Science Behind the Process

The effectiveness of the two-step process lies in the chemical interactions taking place:

- Acidic Pre-soak Reaction

Acidic solutions have a low pH, which enables them to dissolve and weaken inorganic materials like calcium and magnesium deposits found in hard water. Road film often contains these deposits, making the acidic pre-soak an ideal starting point.

- Alkaline Detergent Reaction

Alkaline cleaners, with their high pH, are best for breaking down organic residues like oils and fats. The presence of surfactants in these detergents reduces surface tension, allowing the solution to penetrate grime more effectively and lift it away from the paintwork.

This pH-based approach not only maximizes cleaning performance but also minimizes the need for high-pressure scrubbing, which brings us to the advantages of this process in touchless systems.

Why the Two-step Method Shines in Touchless Wash Systems

Touchless car washes offer convenience and protection for vehicle surfaces, as they eliminate the need for brushes or physical contact that could cause micro-scratches. However, because these systems rely solely on chemicals and water pressure, they need highly effective cleaning solutions. The two-step process is ideal here due to its ability to:

- Remove Road Film Without Contact: The acidic and alkaline solutions work synergistically to dislodge even the toughest contaminants without requiring physical scrubbing. This is crucial for removing films that traditional soap-and-water methods often leave behind.

- Maintain Vehicle Appearance: By removing dirt and grime effectively without abrasive contact, the two-step method helps preserve a vehicle’s paint and finish over time.

- Optimize Chemical Use: The acid-alkaline combination ensures that cleaning agents are used efficiently by targeting specific contaminant types, reducing the need for excessive chemical quantities.

Key Benefits of the Two-step Process

Beyond its compatibility with touchless systems, the two-step wash process offers several additional benefits for both operators and end-users:

- Eco-friendly Potential: When used in calibrated quantities, the process minimizes water and chemical waste. Many modern systems also feature water recycling technologies to enhance eco-friendliness.

- Time Efficiency: The chemical reactions in a two-step process work quickly, which makes for shorter wash cycles and higher throughput in commercial settings.

- Cost-effectiveness: By targeting different contaminants effectively, the method reduces the need for repeat washes, translating into cost savings for both businesses and customers.

- Versatility Across Vehicles: This process can be tailored to suit a wide range of vehicles, from sedans to large trucks, by adjusting the chemical concentrations and application techniques.

Practical Tips for Implementing the Two-step Process

For businesses and individuals looking to adopt this method, here are some helpful tips for successful implementation:

- Choose High-quality Products: Select professional-grade acidic and alkaline cleaning agents that are specifically formulated for vehicle washing. Look for solutions that are safe for use on various finishes, including clear coats and chrome.

- Use Proper Equipment: Touchless systems with controlled spray nozzles and pressure settings ensure even application and optimal performance of the cleaning agents.

- Follow Manufacturer Guidelines: Adhere to the recommended dilution ratios and contact times for both the acid pre-soak and alkaline detergent. Overuse of these chemicals could damage vehicle surfaces or negatively impact the environment.

- Calibrate for Local Water Conditions: Hard or soft water can affect cleaning efficiency, so adjust chemical mixtures accordingly to achieve the best results.

- Perform Regular Maintenance: Keep equipment like sprayers and pumps in excellent working condition to ensure consistent application of the cleaning solutions.

Considerations for Users

While the two-step process is highly effective, there are a few considerations to keep in mind to ensure optimal results and safety:

- Protective Measures for Staff: Acidic and alkaline solutions can be hazardous if mishandled. Always provide appropriate PPE (personal protective equipment), including gloves, goggles, and aprons, for operators.

- Environmental Impact: Ensure compliance with environmental regulations regarding the use and disposal of cleaning chemicals. Using biodegradable or environmentally friendly formulations is preferable.

- Compatibility with Materials: Check that the cleaning agents are compatible with the surfaces of the vehicles being treated, especially for specialty finishes or older models.

Final Thoughts

The two-step washing process is an exceptional advancement in vehicle cleaning, providing a powerful yet gentle solution for touchless wash systems. By leveraging the unique properties of acidic pre-soaks and alkaline detergents, this method removes even the most stubborn road film while safeguarding vehicle surfaces.

Whether you’re a car wash operator aiming to improve efficiency or a vehicle owner seeking reliable results, this method adds value with its effectiveness, cost savings, and compatibility. Proper implementation, attention to safety, and environmental mindfulness will ensure you maximize the benefits of this innovative approach.