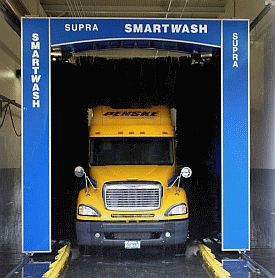

Automated, Touchless Tractor Washing

LazrTek’s advanced touchless gantry wash system offers custom solutions tailored to specific applications. Our leading-edge technologies allow our systems to learn how to wash a vehicle, a progressive automated solution that replicates manual washing.

Powerful sprays contour vehicle shape in strategic sequence to optimize cleaning. Advanced automation yields consistent results for super clean tractors.

Touchless Gantry Wash System Best Features

Flexible Wash Cycles

Customize wash programs for different vehicle types and dirt conditions variable at different times of the year and weather conditions.

Environmentally Friendly

Responsible recycled water and solids management systems means less water used, and discharge water that meets sanitary requirements. Chemicals are bio-degradable and meet all EPA safety standards for non-toxic applications.

Damage-Free

The touchless system is void of abrasive brushes that may strip equipment from a Tractor such as antennae’s, aftermarket lights, satellites, exhaust stacks, fender flares, etc. The touchless system utilizes high-pressure low volume pumps that produce 1000psi to remove dirt and grime without harming the truck or its accessories.

A Smart Touchless Wash System

An advanced gantry wash system offers custom solutions tailored to specific applications.

Our leading-edge technologies allow our systems to be taught how to wash a vehicle, a progressive automated solution that replicates manual washing and gets a vehicle super clean without brushes due to the consistent distance of the spray nozzles and spinners from the vehicle surface maximizing pressure and cleaning fluids effectiveness.

The advanced AI-enhanced 3D mapping allows the smart gantry wash system to profile any size vehicle and create a custom wash that rivals hand washing. Wash Tractors, vans, buses, and any heavy equipment effectively producing a very clean product without labor in under 6 minutes.

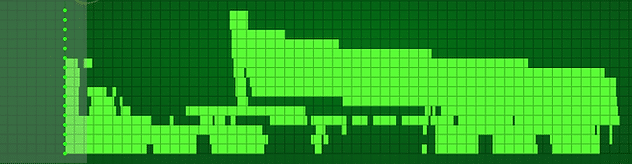

Advanced Scanning Technology – Vehicle 3D Scanning/virtual mapping

An array of sensors passes over the vehicle to create a 3D shape profile of the vehicle. The collected data is analyzed to automatically locate key regions across the vehicle.

Shape Analysis

According to the configuration of the wash program, key regions are located on the raw, scanned shape. Regions can be added, removed and adjusted. Paths for the profiler spray bar and side washers are also generated, which can be adjusted to maximize nozzle spray distance to maintain constant effective pressure and wash detergent and chemical applications.

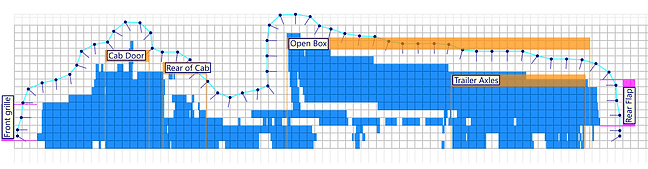

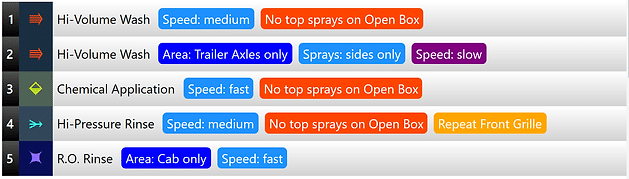

Wash Sequence

A list of modular wash operations is used to orchestrate the various steps in washing the vehicle. These can be linked to located vehicle regions to engage different wash behaviors. They can be edited, duplicated, rearranged, etc. to achieve the ideal wash.

Automation

Sophisticated AI-enhanced algorithms translate geometric paths and wash instructions into smooth, multi-axis robotic motion, synchronized with spray control and articulation making spinners and nozzles operate at maximum effectiveness.

Innovative Features

Scanning

Scanning technology to identify the vehicle shape and key regions

Power Sprays

Combination high-volume and high-pressure oscillating spray heads to match soil conditions

Teaching

Ability to teach machine how to wash vehicle and save as a wash program

Profiler

Fast, efficient cleaning of profile surfaces with dynamic contouring of our 3-axis robotic spray bar

Width & Length Auto-Adjusting

Width & Length adjustments maintain optimal spray distance for varying vehicle widths

Chemistry

Hot water and on-demand multi-chemical spray applications allow for specialized cleaning of various surfaces with variation dependent on weather and seasonal conditions.

Washing Features

Drive-in Pre-wash

Powerful low-volume sprays remove solids from the undercarriage and lower sides of the vehicle as it drives in.

Oscillating Chassis Wash

After the vehicle parks in position, longitudinal undercarriage sprays can be engaged which sweep from side to side.

Gantry

The foundation of the operation, it moves across the length of the vehicle in multiple passes to conduct AI-enhanced 3D profile mapping of the vehicle to conduct consistent optimum spray distance in the various phases of the wash process.

Profiler

This spray bar is equipped with various sprays and contours the vehicle surface. Anti-collision sensors stand guard for vehicle protection.

Width-Adjusting Side Sprays

Side sprays are mounted on trolleys that automatically position themselves to maintain ideal wash distance as vehicle widths vary

Pivoting and Angling

Side spray columns can also pivot fore & aft to better wash certain vehicle surfaces. Optional X-angle spray bars can be installed to wash cylindrical trailers.

Low-Volume Sprays

The pumps utilized consume 1/3 of the water volume of traditional pumps and are highly effective due to the high operating pressure (1000 psi).

High-Pressure Sprays

Powerful jets of water at high pressures do the work of lifting the grime that has been released by applied chemicals

Oscillating Spray Heads

For even coverage of pressurized sprays, the nozzle assemblies sweep up & down as the gantry moves across the vehicle.

Chemical Sprays

Hot water on-demand multi-chemical sprays allow for specialized cleaning of various surfaces, and can be optimized using different nozzle types.

R.O. Sprays

An optional finishing step is to apply reverse-osmosis water to all or a part of the vehicle being washed to achieve spot-free shine

User-Friendly Software

Our POS software was developed from the ground-up to best support the commercial trucking world. For example, bills can be split between tractor and trailer where they represent different companies. Sales history, financial reports, and tools to export data for accounting are also included.

Modern Control Interface

Our proprietary HMI (Human-Machine Interface) technology was created to provide mobile control of all wash equipment remotely. Employing the familiar touch interactions of today’s smart phones and tablet, it is a seamless window into the automation of gantry wash system. Remote access to the system often saves service calls and all equipment monitoring and wash metrics are available via app or software interface for fully transparent operations.

Troubleshooting Support

Technical difficulties are inevitable in gantry wash systems, however we provide supportive tools to resume operations as quickly and pain-free as possible. With real-time faults and messages with troubleshooting tips, remote monitoring and parts & 24 hr. tech support from Little Rock, downtime will be kept to an absolute minimum.

Cleaning Chemistry

- Our systems employ various detergent formulations to meet an array of different cleaning challenges, from etching acids to alkaline-based soaps.

- Chemical concentrations can be varied via speed-controlled metering pumps.

- On-demand hot water is used to deliver chemicals for maximize cleaning effectiveness

- Nozzle types (foaming vs. non-foaming, spray pattern, etc) are expertly selected for optimal washing per application

Recycled Water Management System

Our specialized equipment works in the background to recover as much reusable water as possible. Debris and silt are separated, and the remaining water is treated to prevent stagnation.

Water Recycling

If necessary or required, our specialized equipment works in the background to recover as much reusable water as possible. Debris and silt are separated, and the remaining water is treated to prevent stagnation.

Solids Management

Whatever dirt is carried into the bay on a tractor may be removed from the system if required. Our patented approach to separating, de-watering and preparing solids for removal makes dealing with waste as painless and inexpensive as possible.

Special Waste Handling

If you have special waste water and/or solids removal requirements, we can engineer custom solutions to meet your unique requirements. From settling pits to automated leeching fields, we can make it work!

Pros & Cons:

Traditional Gantry Wash System with Brushes vs Automated Highspeed Drive-Thru Truck Wash vs Highspeed Touchless AI-enhanced Computer-profiling Gantry Wash System

Traditional Gantry Wash System with Brushes

Pros:

- A gantry wash system takes up limited space due to its compact size.

- It does a decent job at cleaning a tractor and van trailer.

- It will always wash at the same speed, versus the variable rate of pressure washing.

- It will give you a consistent wash.

Cons:

- Gantry washes with brushes have nearly 10 times the maintenance costs due to all of the moving parts that are required to operate it.

- It takes approximately 10-15 min. for a driver to complete an entire wash.

- There are a limited number of trucks and trailers you can wash per day.

- There may be additional detailing time if the initial wash did not clean irregular surfaces

- Drivers sacrifice valuable road time waiting to use the wash and waiting for a wash to complete.

- Irregularly shaped trucks, such as vacuum and garbage trucks, or tractors behind the cab are practically impossible to fully clean with a traditional gantry brush wash.

- Non-typical trailers such as tankers, ribbed sided, or flatbed trailers will never be fully cleaned without using manual labor and a pressure washer. This is the reason pressure washers are sold with all gantry systems.

- Brushes typically create micro-abrasions on a vehicle’s surface. This dulls paint surfaces more quickly and speeds up the deterioration of any decals on a vehicle.

- Damages to special vehicle add-ons like antennaes, LED lights, satellites, etc. are frequent.

High Speed Touchless Drive Thru Wash

Pros:

- A Drive Thru wash has minimal maintenance costs.

- A touchless Drive thru system is designed to have the smallest number of moving parts possible.

- Service is reduced to a minimum due to the reliability of our systems.

- It takes approximately 4 ½ min. to completely wash a 70’ tractor trailer and only 2 ½ for tractor only. You can wash many vehicles in a single day

- Drivers won’t be sacrificing their road time waiting in line to get their vehicle washed

- Waits for a drive thru wash are rare due to their inherent efficiency.

- All types of trucks and trailers get a complete clean from top to bottom without the need for brushes. A Drive Thru wash has less liability risk

- The drivers never need to exit their vehicles while in the wash bay.

- Drivers move through the wash at approximately 1 foot per second (Creeper gear). There are also guide rails to prevent the driver from steering their vehicle into the wash gear.

- Drivers are guided through the wash using our Smart Driver Pace Light System. This utilizes High Intensity LED lights to ensure they are moving at the proper speed. Most drivers are using a wash to get their truck and trailers clean and will move at the proper speed to ensure this happens.

- They can be installed in most buildings that a Gantry style wash has been installed.

- Approximately 30% of our new business comes from company’s swapping out their Gantry wash and replacing it with a drive thru. We are able to utilize the same building their previous wash was in.

- A drive thru truck wash can be 100% customized to address the fleet owner’s special needs, road, weather and seasonal conditions.

Cons:

- The quality of the wash can be affected by drivers who may drive too fast through the wash.

- However, drivers typically want their truck clean and will use the smart driver pace lights to ensure a proper wash.

Highspeed Touchless Gantry Wash System:

Pros:

- A gantry wash system takes up limited space due to its compact size.

- It does an excellent job of cleaning a tractor and van trailer due to AI enhanced profiling software to develop optimum consistent spray nozzle distance to increase detergent and chemical effectiveness as well as rinse.

- It will always wash at the same speed, versus the variable rate of pressure washing.

- It will provide a customized consistent wash similar to a hand wash.

- Touchless washes are inherently less maintenance than with brushes and the gantry profiler requires only slightly more maintenance than touchless drive-through.

- Takes only 4 ½ mins to wash a tractor

- Water consumption and soap and chemical consumption minimized due the profiling algorithm providing wash efficiency.

- The touchless profiling Gantry can be fully customized to address special fleet owner’s needs, road, weather and seasonal conditions.

- Consistent washes since the driver does not operate the tractor during the wash

- No damages due to not having abrasive brushes.

- Less water consumption.

- Consistency and flexibility of wash

Cons:

- More moving parts than a drive through.

- Slightly more maintenance but all parts & labor provided by LazrTek

LazrTek custom designs truck wash solutions for fleet customers throughout the united states. With our chemical partner, Enviro-chem, we ensure our customer’s needs are met while guaranteeing speed, price transparency, and convenience. We currently provide custom wash solutions for Walmart, FedEx, Kroger, Ashley Homestore, WinCo foods, Cooper Trucking and other national accounts.

LazrTek truck wash systems enhance tractor and trailer utility while reliably delivering clean trucks and trailers at an affordable price, LazrTek customers enjoy clean equipment, happy drivers, good corporate imaging, and sparkling trucks with the dependability of parts, service, soap, and chemicals in the wash bay.

LazrTek truck wash equipment is state of the art, reduces water consumption, is environmentally safe and all soaps and chemicals are biodegradable. LazrTek wash systems meet all EPA requirements and local environmental quality standards.

For more information, contact Harold@LazrTek.com or call (469) 536-8478.