Revolutionizing tractor trailer maintenance has become a game-changer in the transportation industry. The power of undercarriage and wheel blaster wash systems is transforming how fleet owners and operators maintain their vehicles, improving efficiency, and reducing downtime. In this article, we delve into the innovative technology behind these systems and explore their numerous benefits.

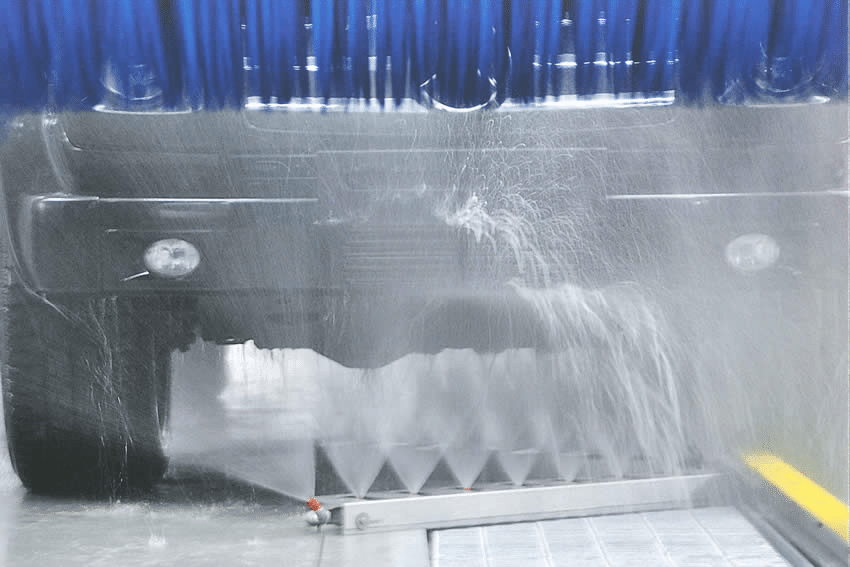

Utilizing cutting-edge engineering, undercarriage and wheel blaster wash systems provide a comprehensive and thorough cleaning solution for tractor trailers. By deploying high-pressure water jets and specialized detergents, these systems effectively remove dirt, debris, and road grime, ensuring a pristine and well-maintained undercarriage and wheels.

With regular use of undercarriage and wheel blaster wash systems, fleet owners can prevent costly repairs caused by corrosion and build-up. Regular cleaning also helps to maintain optimal performance and extend the lifespan of brake systems, suspensions, and axles.

As the demand for more environmentally friendly practices increases, these advanced wash systems also help to reduce water consumption, making them a sustainable choice for businesses.

Stay tuned as we explore the exceptional capabilities and features of undercarriage and wheel blaster wash systems, highlighting their impact in revolutionizing tractor trailer maintenance.

Importance of undercarriage and wheel cleaning for tractor trailers

When it comes to maintaining a fleet of tractor trailers, keeping the undercarriage and wheels clean is more than just about aesthetics. The undercarriage faces constant exposure to road salt, grime, and debris, which can lead to corrosion and mechanical issues over time. Neglecting this crucial area can result in costly repairs and decreased vehicle lifespan.

Enter automatic wash systems tailored for commercial vehicles. These high-tech solutions are designed to efficiently clean hard-to-reach areas like the undercarriage and wheels with precision. By incorporating advanced technology such as high-pressure water jets, rotating brushes, and chemical application systems, these wash systems ensure thorough cleaning while saving time and labor for fleet operators.

Stay tuned as we delve deeper into the components and integration of these innovative wash systems to understand how they revolutionize fleet maintenance practices!

Undercarriage Wash System Components

When it comes to undercarriage wash systems for tractor trailers, there are key components that ensure a thorough cleaning process.

High-pressure water jets play a crucial role in removing dirt and grime from hard-to-reach areas underneath the vehicle. These powerful jets effectively blast away debris for a comprehensive clean.

Rotating brushes or rollers work in tandem with the water jets to scrub off stubborn residue and provide an extra level of cleanliness. Their motion helps dislodge buildup and leave the undercarriage spotless.

The chemical application system introduces specialized cleaning agents that target grease, oil, and other contaminants, enhancing the overall washing effectiveness. These solutions help break down tough stains for a pristine finish.

A containment and drainage system is essential for collecting wastewater and preventing environmental contamination. Proper disposal methods ensure eco-friendly operations during the wash process.

Control panel and automation features streamline operations by allowing users to program wash cycles, monitor progress, and maintain safety standards with ease. These advanced controls enhance efficiency while ensuring optimal results every time.

Wheel Blaster Wash System Components

When it comes to the wheel blaster wash system components, each element plays a crucial role in ensuring a thorough and efficient cleaning process for tractor trailers.

Starting with the high-pressure water nozzles, these powerful jets are strategically positioned to target dirt and grime even in hard-to-reach areas. They work together with rotating or oscillating brushes that provide additional scrubbing power to eliminate stubborn debris.

The chemical application system complements the cleaning process by applying specialized detergents or degreasers that help break down grease and oil buildup on wheels and undercarriage. This ensures a deep clean for optimal maintenance.

Wheel positioning and alignment mechanisms ensure precise placement of the vehicle within the wash system, allowing for consistent coverage and thorough cleaning. The containment and drainage system efficiently collects wastewater, preventing environmental contamination.

Moreover, the control panel and automation features offer users convenient programming options for customizable wash cycles, enhancing user experience while maintaining safety standards during operation.

Detailed Description of Components

When it comes to the detailed components of an automatic wash system for tractor trailers, each aspect plays a crucial role in ensuring thorough cleaning.

Starting with high-pressure water jets, their strategic placement and orientation are designed for effective removal of dirt and grime from hard-to-reach areas under the vehicle. The water pressure and flow rate specifications are carefully calibrated to provide optimal cleaning power without causing damage.

Next, we have brushes or rollers made from materials like nylon or polyethylene that aid in scrubbing off stubborn residues. Their rotational speed and direction control allow for customizable cleaning based on the level of soiling.

The chemical application system is responsible for applying detergents or degreasers effectively onto the surfaces through spray nozzles or foam applicators. This step ensures a deep cleanse while being gentle on the vehicle’s components.

The containment and drainage system collects wastewater and debris efficiently, with options for recycling or proper disposal methods in place. This eco-friendly approach minimizes environmental impact.

The control panel and automation features offer programmable wash cycles, user-friendly interfaces for manual control and monitoring, as well as safety measures like emergency stop buttons and motion sensors to ensure a smooth operation every time.

Integration and Compatibility

When it comes to integrating undercarriage and wheel blaster wash systems for tractor trailers, several key factors need to be considered. Installation considerations play a crucial role in determining the efficiency of the wash system. Different types of wash bays or facilities may require specific adjustments for seamless integration.

Compatibility with existing fleet management systems is another essential aspect to address. Ensuring that the automatic wash system can communicate effectively with other operational software can streamline maintenance processes and enhance overall performance.

Maintenance requirements and service intervals are vital for optimal functionality. Regular upkeep not only ensures consistent cleaning results but also prolongs the lifespan of the equipment. Adhering to scheduled maintenance routines is key to maximizing the benefits of automated wash systems in fleet management operations.

Benefits of Automatic Wash Systems for Tractor Trailers

Automatic wash systems for tractor trailers offer a myriad of benefits that go beyond just keeping the vehicles looking clean. They provide improved cleaning effectiveness and consistency by utilizing high-pressure water jets, rotating brushes, and chemical application systems to ensure thorough cleaning of the undercarriage and wheels.

Moreover, these systems save valuable time and labor compared to manual washing methods. Fleet operators can optimize their resources more efficiently while maintaining a higher level of cleanliness for their vehicles.

In addition to operational efficiency gains, automatic wash systems contribute to reducing environmental impact through optimized water and chemical usage. By recycling wastewater and using eco-friendly detergents, these systems help minimize harmful runoff into the environment.

Furthermore, the extended lifespan of vehicle components due to regular undercarriage and wheel cleaning results in reduced maintenance costs over time. By preventing corrosion, rust build-up, and other damages caused by neglecting underside cleaning, fleet operators can prolong the longevity of their assets.

Case Studies or Examples

Fleet operators across the country have been reaping the benefits of integrating automatic wash systems for their tractor trailers. Case studies have shown significant improvements in vehicle cleanliness, maintenance, and cost savings after implementing these advanced cleaning solutions.

By investing in undercarriage and wheel blaster wash systems, fleet operators have witnessed a remarkable enhancement in the overall appearance of their vehicles. The high-pressure water jets and rotating brushes ensure thorough cleaning even in hard-to-reach areas, resulting in spotless trucks that leave a lasting impression on the road.

Moreover, the quantifiable benefits extend beyond just aesthetics. Maintenance costs have significantly reduced as regular washing helps prevent corrosion and damage to crucial components underneath the vehicles. This proactive approach not only prolongs the lifespan of the fleet but also minimizes unexpected repair expenses.

Additionally, fleet operators have reported substantial cost savings by transitioning from manual washing methods to automated systems. The efficiency and consistency achieved through automatic wash systems translate into time saved on labor-intensive cleaning routines – a win-win situation for both operational productivity and budget management.

Challenges and Considerations

When considering the integration of an automatic undercarriage and wheel wash system for tractor trailers, several challenges and considerations should be taken into account.

Fleet operators may face initial investment costs associated with purchasing and installing the wash system. However, conducting a thorough return on investment analysis can help determine long-term cost savings from reduced manual labor and maintenance expenses.

Compatibility with different vehicle configurations and sizes is another key consideration. Ensuring that the wash system can effectively accommodate various types of tractor trailers is essential for optimal performance.

Moreover, potential limitations in extreme weather conditions or heavily soiled vehicles should also be evaluated. Adapting to challenging environments or dealing with exceptionally dirty trucks may require additional maintenance or operational adjustments to maintain efficiency.

Summary of key components and features of automatic wash systems for tractor trailers

Automatic wash systems for tractor trailers play a vital role in maintaining fleet cleanliness and prolonging the lifespan of vehicles. The key components, such as high-pressure undercarriage wash systems and wheel blasters, ensure thorough cleaning and efficient maintenance. Regular undercarriage and wheel cleaning are essential for preventing corrosion, improving safety on the road, and reducing costly repairs.

For fleet operators looking to enhance their maintenance practices, investing in automatic wash systems is a wise decision. These systems offer improved cleaning effectiveness, time savings compared to manual washing methods, and reduced environmental impact through optimized water and chemical usage. By integrating automated wash systems into their operations, fleet operators can benefit from increased efficiency, lower maintenance costs, and overall enhanced vehicle performance.

Prioritizing undercarriage and wheel cleaning through the implementation of automatic wash systems is key to ensuring the longevity and reliability of tractor trailers in commercial fleets. Fleet operators should consider these recommendations when evaluating the integration of automatic wash systems into their maintenance protocols for optimal results.