LazrTek Bus Wash System Comparison

See the comparison below for positives and negatives of each drive thru bus wash system from LazrTek.

Automated Touchless Drive-Thru Bus Wash System vs. Touchless Gantry Computer-Lazer-Profiling Bus Wash System vs. Traditional Brush Wash System vs. Mobile Bus Wash System

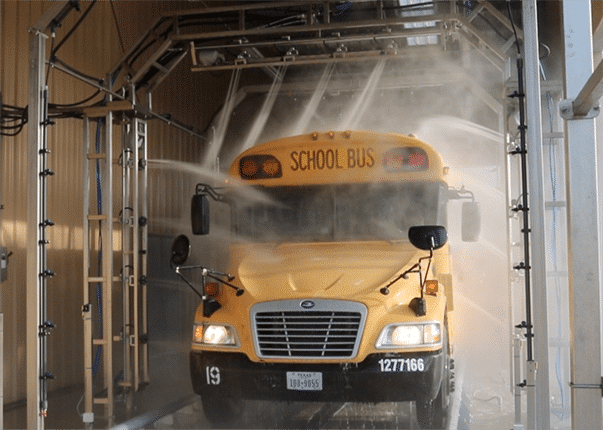

Automated Touchless Drive Thru Bus Wash

Positives:

- A Drive Thru bus wash delivers a good wash product with minimal maintenance costs and limited down-time. In fact, LazrTek provides all parts and labor for repairs in the touchless drive through wash contract.

- A LazrTek Touchless Drive thru system is designed to have the fewest number of moving parts possible which cuts down-time and maintenance.

- We do not support our business by billing for service, but by word of mouth about how reliable and maintenance-free our wash systems are and how clean we get the buses.

- It takes approximately 2 ½ min. to completely wash a 40’ Bus. You can wash many vehicles in a single day

- Drivers won’t be sacrificing their road time waiting in line to get their vehicle washed

- Waits for a drive thru wash are rare due to their inherent efficiency.

- All types of Buss and trailers get a complete clean from top to bottom without the need for brushes.

- A drive thru is safer for the driver because they aren’t walking along a soapy and wet surface and never have to get out of the bus. The drivers never need to exit their vehicles while in the wash bay.

- Drivers move through the wash at approximately 1 foot per second (Creeper gear). There are also guide rails to prevent the driver from steering their vehicle into the wash gear.

- Drivers are guided through the wash using our Smart Driver Pace Light System. This utilizes High Intensity LED lights to ensure they are moving at the proper speed. Most drivers are using a wash to get their Bus and trailers clean and will move at the proper speed to ensure this happens.

- They can be installed in most buildings that a Gantry style wash has been installed or may be utilized outdoors without a building. A cover is recommended to ensure rainwater does not mix with biodegradable chemicals and soaps.

- Approximately 30% of our new business comes from bus fleet management companies swapping out their Gantry washes and replacing them with a touchless drive thru or touchless profiling Gantry.

- We are consistently able to utilize the same building or concrete drivewaytheir previous wash was housed.

- A drive through Bus wash can be 100% customized to address the fleet owner’s needs and wash policy.

- Our touchless drive-through wash systems typically reduce labor by at least 2/3rds

- Touchless drive through wash systems use less chemical, soap and water (1/3 to 2/3rds less) than a traditional brush Gantry or 2-step hand wash wand system.

Negatives:

- The quality of the wash can be slightly affected by drivers who ignore smart pacer lights & drive too fast through the wash.

- Drivers typically want their Bus clean and will use the smart driver pace lights, once comfortable to ensure a proper wash.

- The first time a driver goes through a drive-thru wash, the high-intensity, high-pressure, low water volume rinse portion can be slightly disorienting.

- Customarily, the second time through the wash, this feeling dissipates. The more drivers use the wash, the more comfortable they will become.

Touchless Gantry Computerized-Lazer Guided 3D-Profiling Wash System

Positives:

- A touchless gantry-computerized profiling wash consumes limited space due to its compact size.

- It does a good job of cleaning a Bus with irregular surfaces utilizing computerized automatic Laser guided profiling automation keeping the jets consistently 18 inches from all surfaces.

- The computerized 3D-profiling system allows exact distance nozzle directions to wash multiple sizes and shapes of vehicles from automobiles, trucks, tractor trailers, buses, RVs, Vans, and heavy equipment.

- It will always wash at the same speed, versus the variable rate of pressure washing.

- It will provide a consistent wash.

- A touchless Gantry is safer for the driver because they aren’t walking along a soapy and wet surface to walk to a lobby. The drivers never need to exit their vehicles while in the wash bay.

- Uses less chemical, soap and water (1/3-2/3rds less) than a traditional brush Gantry or 2-step wand handwash.

Negatives:

- Touchless computerized 3-D profiling/mapping Gantry washes take an extra minute or two for the computer to profile the vehicle before washing, therefore average wash time is about 6 minutes.

Traditional Brush Wash System (Traditional Gantry)

Positives:

- A gantry-style wash brush wash consumes limited space due to its compact size.

- It does a good job of cleaning a Bus, especially a school bus because low pressure pumps are utilized which limits water leakage through windows and bus body riveted body joints.

- It will always wash at the same speed, versus the variable rate of pressure washing.

- It will give you a consistent wash resulting in a very clean bus.

Negatives:

- Brush Gantry washes have greater maintenance costs due to all of the moving parts that are required to operate it.

- It takes approximately 10 min. or more for a driver to complete an entire wash which cuts utility and may interrupt bus schedules.

- There are a limited number of Bus and trailers you can wash per day.

- There may be additional detailing time if the initial wash did not clean irregular surfaces

- Drivers sacrifice valuable road time waiting to use the wash and waiting for a wash to complete.

- Irregularly shaped Buses are practically impossible to clean with a traditional gantry wash.

- Non-typical shaped buses and the backs of tractor cabs will never be fully cleaned without using manual labor and a pressure washer because the brushes cannot reach every spot on the bus such as behind the mirrors. This is the reason pressure washers are sold and installed with all gantry brush systems.

- Brushes sometimes create micro-abrasions on a bus surface. Micro-abrasions dull paint surfaces more quickly and speeds up the deterioration of clear coat and any decals and/or image wrapping on a vehicle.

Mobile Bus Wash System

Positives:

- Fast: 6 minutes for soap, wash, and rinse a school bus and can wash continuously upto 30 vehicles on a single charge.

- Clean: No matter what’s on the vehicle, LazrTek wash unit can bring back your bus to be a perfect-clean, bright, and shine bus again.

- Convenience: Effortlessly, you don’t need to move your bus fleet around. Just move the LazrTek Bus Wash machine and get the job done anywhere!

Negatives:

- The machine requires an operator to move the wash unit around the bus.

- A single charge can wash upto 30 buses.

Get Started Today

If you’re in charge of cleaning school buses at your district or considering washing fleets of buses, it really does help to use LazrTek bus wash system. If you would like assistance with your school bus imaging and wash systems, contact LazrTek by email Harold@Mach1Design.com or call (469) 536-8478.