Welcome to a closer examination of the cutting-edge technology powering automatic wash systems: 3-D gantry profiling through laser technology. In this article, we will delve into the science behind this innovative system and explore the benefits it offers for optimized cleaning results.

Laser technology has revolutionized the car wash industry by providing precise and efficient profiling capabilities. With 3-D gantry profiling, the lasers are used to map the contours and dimensions of a vehicle, ensuring precise positioning and targeting of the cleaning agents. This results in a more thorough and effective cleaning process, eliminating missed spots and enhancing the overall quality of the wash.

By incorporating laser technology, automatic wash systems can deliver exceptional results while minimizing the risk of damage to vehicles. The precise profiling ensures that the cleaning agents are applied only where needed, reducing wastage and enhancing efficiency.

With the help of laser technology, automatic wash systems can provide a consistent, high-quality cleaning experience, enhancing customer satisfaction and encouraging repeat business. Stay tuned as we explore the science behind 3-D gantry profiling and its impact on the car wash industry.

What is laser technology in automatic wash systems?

Laser technology has revolutionized the car wash industry by providing precise and efficient profiling capabilities. Unlike traditional wash systems that rely on manual adjustments and guesswork, laser technology allows for accurate and automated profiling of vehicles. By using lasers to map the contours and dimensions of a vehicle, automatic wash systems can ensure precise positioning and targeting of the cleaning agents. This results in a more thorough and effective cleaning process, eliminating missed spots and enhancing the overall quality of the wash.

Laser technology in automatic wash systems is a game-changer because it brings a level of precision and consistency that was previously unattainable. With the ability to precisely measure and map the surface of a vehicle, the system can adapt to different vehicle types and shapes, ensuring optimal cleaning results every time. This technology allows for a customized wash experience that meets the unique needs of each vehicle.

The benefits of laser technology in automatic wash systems extend beyond just the cleaning process. By incorporating laser profiling, these systems can deliver exceptional results while minimizing the risk of damage to vehicles. The precise profiling ensures that the cleaning agents are applied only where needed, reducing wastage and enhancing efficiency. Additionally, the automation provided by laser technology allows for faster wash cycles, increasing the throughput and revenue potential for car wash operators.

Benefits of 3-D Gantry Profiling

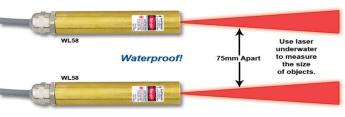

The process of 3-D gantry profiling begins with the use of laser scanners that emit a laser beam towards the vehicle. These scanners are strategically positioned on a gantry system that moves along the length of the vehicle. The laser beam emitted by the scanners is reflected back to the sensors, providing valuable data on the shape, contours, and dimensions of the vehicle’s surface.

Using this data, the automatic wash system’s software creates a digital model of the vehicle, accurately capturing its unique characteristics. This model is then used to determine the optimal positioning and movement of the cleaning agents. By precisely targeting the cleaning agents, the system ensures that every part of the vehicle is thoroughly cleaned, leaving no missed spots or areas.

To further enhance the cleaning process, the software can also adjust the application of the cleaning agents based on the level of dirt or grime detected on different parts of the vehicle. This adaptive cleaning approach ensures that heavily soiled areas receive more attention, while cleaner areas are treated with a lighter touch, optimizing both cleaning performance and efficiency.

How does 3-D Gantry Profiling work?

The benefits of 3-D gantry profiling in automatic wash systems are numerous. Firstly, it ensures a consistent and high-quality cleaning experience for customers. By precisely mapping the contours and dimensions of each vehicle, the system can adapt to different shapes and sizes, providing a customized cleaning experience that meets the unique needs of each vehicle.

Secondly, 3-D gantry profiling improves the efficiency of the cleaning process. With accurate profiling, the system can apply the cleaning agents only where needed, reducing wastage and optimizing the use of resources. This not only saves costs but also minimizes the environmental impact of the wash process.

Thirdly, the use of laser technology in automatic wash systems enhances customer satisfaction. The precise targeting of the cleaning agents ensures that every part of the vehicle receives the necessary attention, resulting in a thorough and effective clean. This attention to detail enhances the overall appearance of the vehicle and leaves customers highly satisfied with the wash results.

Applications of 3-D Gantry Profiling

The applications of 3-D gantry profiling extend beyond the car wash industry. This innovative technology has found success in various industries where precise and efficient cleaning is required. For example, it is being utilized in the aviation industry to clean aircraft exteriors, ensuring that every surface is thoroughly cleaned and free from contaminants. In the manufacturing sector, 3-D gantry profiling is used to clean intricate machinery and equipment, ensuring optimal performance and longevity.

The versatility of 3-D gantry profiling makes it a valuable tool in any industry that requires precise and efficient cleaning. Its ability to adapt to different surfaces and shapes, combined with the accuracy provided by laser technology, makes it an ideal solution for a wide range of applications.

Advancements in laser technology for automatic wash systems

As technology continues to evolve, so does laser technology in automatic wash systems. Advancements in laser sensors and scanning technology have further improved the accuracy and speed of the profiling process. This allows for even more precise targeting of the cleaning agents, resulting in an enhanced wash experience.

Additionally, the integration of artificial intelligence (AI) and machine learning algorithms has brought further advancements to the field of automatic wash systems. These technologies enable the system to learn and adapt to different vehicle types, surfaces, and cleaning requirements, further optimizing the cleaning process.

Choosing the right 3-D Gantry Profiling system

When selecting a 3-D gantry profiling system for your automatic wash facility, several factors need to be considered. Firstly, the accuracy and reliability of the system are crucial. Look for a system that provides precise profiling results consistently, ensuring optimal cleaning performance.

Secondly, consider the ease of integration and compatibility of the system with your existing infrastructure. A system that seamlessly integrates with your wash facility can help minimize downtime and ensure a smooth transition to the new technology.

Lastly, consider the level of support and service provided by the system’s manufacturer. A reliable and responsive support team can assist with any technical issues or questions that may arise, ensuring the smooth operation of the system.

Common challenges and solutions in 3-D Gantry Profiling

While 3-D gantry profiling has revolutionized the automatic wash industry, it does come with its own set of challenges. One common challenge is maintaining accurate profiling results in adverse weather conditions, such as rain or snow. These conditions can affect the laser beams’ reflection and accuracy, potentially leading to compromised cleaning results. However, advancements in laser technology and the use of advanced algorithms have helped mitigate these challenges, ensuring accurate profiling even in challenging weather conditions.

Another challenge is the potential for false positives or false negatives in the profiling process. False positives occur when the system identifies a spot as dirty when it is actually clean, leading to unnecessary cleaning and resource wastage. False negatives, on the other hand, occur when the system fails to identify a dirty spot, resulting in missed cleaning opportunities. To address these challenges, continuous improvements in software algorithms and machine learning models are being made to enhance the system’s accuracy and reduce false readings.

Case studies: Success stories of 3-D Gantry Profiling in different industries

To truly understand the impact of 3-D gantry profiling in automatic wash systems, let’s explore some real-world case studies. In the aviation industry, a major airline implemented 3-D gantry profiling in their aircraft cleaning process. By accurately mapping the exterior surfaces of their planes, they were able to achieve a higher level of cleanliness and reduce cleaning time by 30%. This resulted in significant cost savings and improved customer satisfaction.

In the manufacturing sector, a leading machinery manufacturer adopted 3-D gantry profiling to clean their equipment before shipping to customers. This helped ensure that every machine was delivered in pristine condition, free from any debris or contaminants. The use of laser technology in their cleaning process also allowed them to provide a value-added service to their customers, further enhancing their reputation and customer loyalty.

Conclusion: The future of laser technology in automatic wash systems

As we conclude our exploration of laser technology in automatic wash systems and the science behind 3-D gantry profiling, it is clear that this innovative technology is here to stay. The benefits it offers in terms of precision, efficiency, and customer satisfaction are undeniable. With advancements in laser technology and the integration of AI and machine learning, the future of automatic wash systems looks promising.

In the coming years, we can expect to see further refinements and enhancements to laser technology, making automatic wash systems even more efficient and effective. As customer expectations continue to rise, the need for advanced profiling capabilities will only become more important. By embracing laser technology and 3-D gantry profiling, car wash operators can stay ahead of the competition and provide exceptional cleaning experiences that keep customers coming back for more.

Remember, the science behind 3-D gantry profiling may be complex, but its benefits are clear. Laser technology has revolutionized the automatic wash industry, providing precise and efficient profiling capabilities that deliver exceptional cleaning results. So, embrace the power of laser technology and unlock the full potential of your automatic wash system today.br/>